Your Premier Photoluminescent Pigment Supplier

Get Factory Price Start From 1KG

You need more than just photoluminescent pigments; you need a seasoned partner with decades of specialization to elevate your projects and boost your profits. Let Glowinking illuminate the path to your business success.

Certified Safety for Our Photoluminescent Pigments

Glowinking’s photoluminescent pigments are certified by REACH and RoHS, guaranteeing their safety as non-toxic, harmless, and non-radioactive. Trust in our commitment to eco-friendly and safe materials for any application.

Expert Assistance Awaits

Have more questions or unique requirements? Reach out to our experts today.

Our Pigment With Ultra Bright

Our photoluminescent pigments come in an array of colors, each selected through a rigorous quality control process. This ensures that every pigment we deliver meets the highest standards of glow intensity and color consistency for your projects.

Yellow-Green Color

People just love this color. It is made from strontium aluminate, which glows really bright in the dark.

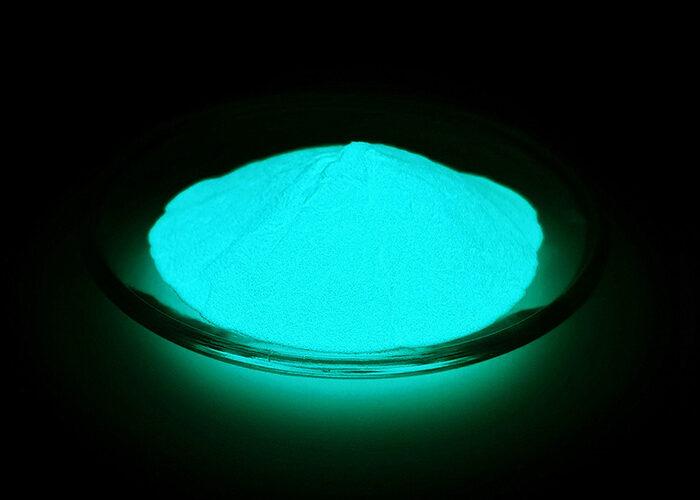

Blue-Green Color

Another strontium aluminate-based pigment, this shade brings a cool, refreshing glow.

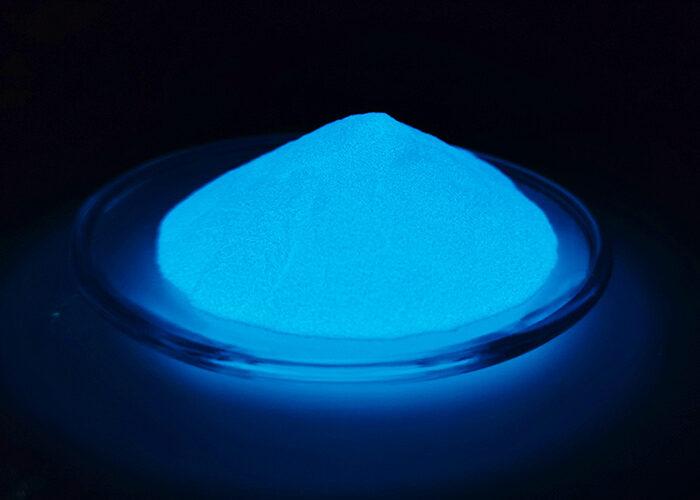

Sky-Blue Color

Made from strontium silicate, this pigment shines with the pure clarity of a cloudless midday sky.

Red Color

Powered by rare-earth sulfides, it glows with the intensity of a sunset’s final moment.

Orange Color

A warm luminescence, ignited by rare-earth sulfides, mirroring a glowing ember.

Purple Color

A blend that captures twilight’s mystery, where passionate red meets deep blue.

Product Features

Discover the core features that make Glowinking’s photoluminescent pigments different. Our pigments are designed to be efficient, long-lasting, and versatile. We made them to perform at the highest level. Find out how these features can change your projects.

Extended Afterglow Duration

Experience the magic of our pigments that glow for up to 12 hours, providing long-lasting visibility and safety in darkness.

Fast Light Absorption

Our pigments achieve full saturation in just 5-15 minutes, ensuring quick and efficient light absorption for immediate luminosity.

Versatile Application

With applications across various industries, our pigments boast high brightness and clear colors, enhancing the quality of any product.

Extended Afterglow Duration

Experience the magic of our pigments that glow for up to 12 hours, providing long-lasting visibility and safety in darkness.

Fast Light Absorption

Our pigments achieve full saturation in just 5-15 minutes, ensuring quick and efficient light absorption for immediate luminosity.

Versatile Application

With applications across various industries, our pigments boast high brightness and clear colors, enhancing the quality of any product.

Why Choose Glowinking?

At Glowinking, we’re lighting the way forward with photoluminescent pigments that do more than just glow. Our mission is to empower your projects with pigments that offer unrivaled brightness, longevity, and eco-efficiency. Based in China and serving the globe, we are your partners in innovation.

20+ Years Expertise

With 20 years of expertise, we deliver unparalleled quality and innovation in photoluminescent pigments.

Eco-Friendly

We prioritize sustainability; our pigments offer energy efficiency without sacrificing performance.

Consistent Quality

Our strict quality control and certification ensure consistent, high-quality pigments every batch.

Instant Assistance

Our dedicated team offers instant help, focusing on quick resolutions to keep your projects moving.

Maximize the Glow: Usage Tips

To fully leverage the unique qualities of our photoluminescent pigments, you must appreciate and adapt to its intricacies. We’ve meticulously studied its behavior across various conditions to provide you with a comprehensive guide. By following these insights, you can enhance, protect, and extend the pigment’s exceptional luminescence for maximum impact.

Stirring When Mixing

The density of photoluminescent pigment is above 3.4g/cm2, which means it tends to settle at the bottom in liquid mediums. To ensure a consistent and uniform application, it’s vital to stir the mixture periodically. This action guarantees that the glow is evenly distributed, giving your project a smooth, radiant finish.

Optimal Mediums

Our photoluminescent pigments are versatile. They naturally excel when combined with oily mediums, providing a rich and uninterrupted glow. However, if your project requires a water-based solution, don’t fret. We’ve engineered a robust waterproof series to cater to such needs, ensuring that the luminosity remains undiluted and vivid.

Avoid Metal Contact

Metals can adversely react with our photoluminescent pigments, potentially causing them to darken or diminish in their glow. It’s essential to handle the pigment with tools that avoid direct metal contact. By doing so, you ensure the pigment’s luminosity remains untouched and pristine.

Choose Transparent

The clearer the medium, the more vibrant the glow. When integrating our pigment, opt for transparent or light-colored materials. These choices allow the pigment to absorb and emit light optimally, ensuring a brighter, more intense radiance.

Mind the Heat

Every substance has its temperature tolerance, and our pigments are no different. While they’re resilient, it’s best to keep them below 700°C. This precaution ensures that their luminescent properties remain intact, and their glow remains as radiant as ever.

Keep It Dry

Proper storage is vital for longevity. Moisture can interfere with the pigment’s properties. By keeping it in a dry environment, you ensure its quality remains undiminished. For those who’ve already opened the packaging, it’s best to reseal it tightly, preserving the pigment’s integrity for future projects.

Shine Brighter in Your Industry!

Join forces with Glowinking and tap into the potential of high-quality photoluminescent pigments. Our dedication to excellence and forward-thinking has enabled numerous partners to achieve remarkable results. Now it’s your turn.

Complete Buyer’s Guide to Photoluminescent Pigments

Learn everything about photoluminescent pigments, including their applications, benefits, and how to choose the right types for your needs. This guide covers essential aspects to help you make informed purchasing decisions.

Table of Contents

What Are Photoluminescent Pigments?

Photoluminescent pigments, also known as glow-in-the-dark pigments, are materials that can absorb and store light energy from various sources, such as sunlight, fluorescent, incandescent light, etc. Once charged, these pigments emit light in darkness, providing a luminous effect. The most common types of photoluminescent materials used today include strontium aluminate and zinc sulfide.

Strontium Aluminate: This is the newer generation of photoluminescent pigments, offering significantly improved brightness and glow duration compared to older types. Strontium aluminate is doped with rare earth elements such as europium and dysprosium, which enhance the light absorption and emission capabilities. It is non-toxic and has the best commercial performance in terms of glow intensity and afterglow time—often glowing for several hours (up to 12 hours or more) after only about 10-15 minutes of light exposure.

Zinc Sulfide: An older type of photoluminescent pigment, zinc sulfide is less bright and has a shorter glow duration than strontium aluminate. It is often activated with copper to improve its glow properties, known as copper-doped zinc sulfide. Zinc sulfide pigments are cheaper and were once widely used for various applications, including watch dials and emergency exit signs.

Both types of pigments are used in a range of applications, from safety signage and egress path marking through to toys, clothing, and decorative items. Their ability to emit light without the need for electrical power makes them incredibly useful in enhancing visibility in dark environments. Additionally, these pigments are valued for their energy efficiency and safety features, as they do not emit harmful radiation and require no electrical power source to function.

Which Material Offers the Longest Glow Duration?

Strontium aluminate is currently the premier choice for applications requiring long-lasting and bright glow-in-the-dark effects, making it a superior material over older alternatives like zinc sulfide.

What makes strontium aluminate exceptional?

Long Glow Duration: Strontium aluminate is known for its impressive glow duration. Once charged by exposure to light, it can continue to emit light for up to 12 hours or more. This extended afterglow period is significantly longer than that of zinc sulfide, which typically fades much quicker.

Brightness: Strontium aluminate pigments are considerably brighter than other photoluminescent materials. This brightness is a result of its crystal structure and the efficient way it absorbs and re-emits light. The material is doped with rare earth elements such as europium and dysprosium, which enhance its photoluminescent properties.

Chemical Stability and Safety: Strontium aluminate is non-toxic and more chemically stable compared to traditional phosphorescent materials. This stability makes it safer for a wide range of applications, including those involving direct contact with humans, such as textiles and toys.

Energy Efficiency: Since these pigments rely solely on absorbed light energy to function and do not require any electrical power, they are considered an eco-friendly lighting solution. They can be used in places where wiring electricity is impractical, reducing energy consumption overall.

Versatility in Applications: Due to its durability and the quality of light emitted, strontium aluminate is suitable for use in various applications, from safety signs and emergency egress systems in buildings to creative projects like arts and crafts, watch dials, and novelty items.

Strontium aluminate’s exceptional glow properties—coupled with its safety and environmental benefits—make it the optimal choice for long-lasting and bright photoluminescent applications. Its ability to perform under various conditions without diminishing in quality or safety underscores its superiority in the field of glow-in-the-dark materials.

What Are the Top Applications for Photoluminescent Pigments?

Photoluminescent pigments, with their capacity to absorb and emit light, are extremely versatile and find applications across a wide range of industries. Here are some of the top uses for these pigments:

Safety Signage and Egress Path Markings: These pigments are commonly used in safety signs, exit signs, and pathway markings that must be visible in the dark, such as in buildings, aircraft, and ships. They help guide occupants safely out of an area during power failures or emergencies.

Paints and Coatings: Photoluminescent pigments are mixed into various paints and coatings for walls and objects that need to glow in the dark. This is popular in both commercial and residential settings for creating unique interior design elements and for enhancing safety.

Resins and Plastics: When mixed into resins or plastics, these pigments can be used to manufacture a variety of products such as glow-in-the-dark toys, buttons, and other decorative or functional items. These materials absorb light during the day and glow during the night, making them appealing and functional.

Textiles and Fibers: Photoluminescent pigments are incorporated into textiles to create fabrics that glow in the dark. These are used in the production of clothing, bags, shoes, and other wearable items that offer both aesthetic appeal and increased visibility.

Emergency and Recreational Equipment: They are used in various types of emergency equipment, such as vests, flashlights, and helmets, as well as in camping gear like tents and ropes, enhancing visibility and safety in low-light conditions.

Art and Decor: Artists and decorators use photoluminescent pigments to add a glowing effect to artworks, sculptures, furniture, and ceramics, creating pieces that transform under different lighting conditions.

Commercial Products: These pigments are also used in commercial products such as watches, clocks, and electronic device interfaces to allow them to be seen in the dark.

These applications demonstrate the broad utility of photoluminescent pigments, leveraging their unique properties to enhance visibility, safety, and aesthetics in a variety of settings.

Can Photoluminescent Pigments Be Used in Dark Paints?

No, photoluminescent pigments cannot effectively be used in dark paints due to their need for light exposure to charge. Dark colors absorb much of the light, inhibiting the pigments’ ability to glow. For optimal glow, the base should be at least semi-transparent because darker materials obstruct light absorption and emission, preventing the pigments from functioning effectively.

How Long Do Photoluminescent Pigments Last?

Glowinking’s photoluminescent pigments are renowned for their long-lasting glow. Typically, our high-quality pigments can glow visibly for up to 12 hours after being sufficiently charged by a light source. However, through meticulous testing, our best pigments have demonstrated the ability to maintain a brightness of 0.32 mcd/m2 for more than 30 hours, though the perceived duration of the glow can vary based on factors such as viewing distance and individual visual acuity.

Factors Influencing Glow Duration:

High Purity Composition: With 99.9% strontium aluminate, our pigments provide a brighter and longer-lasting glow. This high level of purity enhances both the intensity and duration of the emitted light.

Charging Light: The intensity and duration of the exposure to light sources significantly affect the glow. More robust and prolonged exposure to direct sunlight or UV light will yield a longer-lasting glow.

Particle Size: The size of the pigment particles influences the glow duration. Larger particles generally store more light energy, which can extend the duration of the glow.

Background Color: The substrate color impacts the glow’s visibility and duration. Light-colored backgrounds enhance the visibility and apparent duration of the glow by reflecting more light.

Environmental Factors: Ambient light levels, temperature, and humidity can also affect how long the glow lasts. Cooler, darker environments are ideal for a longer-lasting glow.

By ensuring the use of high-purity strontium aluminate and optimal particle sizes, Glowinking’s photoluminescent pigments are engineered to meet the highest standards, providing reliable and enduring luminosity suitable for a variety of applications.

Is It Possible to Use Photoluminescent Pigments in Water-Based Formulas?

Normally, photoluminescent pigments are not suitable for water-based formulas due to their hydrophobic nature. However, by encapsulating the pigments, we can achieve waterproof properties that allow for effective use in such environments.

Are There Fine and Bright Photoluminescent Pigments Available?

Yes, Glowinking specializes in finely milled photoluminescent pigments. Our pigments, with a particle size of less than 400 mesh, deliver an impressive afterglow of over 60 MCD/M2 at 60 minutes. This fine granularity ensures a uniform distribution and consistent glow, enhanced by the vibrant yellow hue of the pigments. These qualities make our pigments ideal for applications demanding high brightness and even coverage.

What Is the Smallest Micron Size Available for Photoluminescent Pigments?

Glowinking offers some of the finest photoluminescent pigments available, with particle sizes as small as approximately 5 microns (D50). This ultra-fine size is perfect for applications like glowing fibers, where exceptional brightness and precise detail are essential, clearly outperforming our competitors.

Why Does Photoluminescent Pigment Brightness Fade Quickly Sometimes?

The brightness of photoluminescent pigments can fade quickly sometimes due to several factors that influence their ability to absorb, store, and emit light effectively. Here are the primary reasons and how to address them:

Insufficient Charging Light: Photoluminescent pigments need adequate exposure to a light source to charge fully. Insufficient light exposure will result in a weaker or shorter-lasting glow.

Type of Light Source: The type of light used for charging can also impact the brightness. UV light and sunlight are the most effective for charging these pigments, whereas some artificial lights may not provide enough energy for a full charge.

Pigment Quality: The chemical composition and quality of the pigments themselves are crucial. High-quality, properly formulated photoluminescent pigments will retain brightness longer than lower quality alternatives.

Environmental Factors: External conditions such as ambient light, humidity, and temperature can affect glow duration. High ambient light can make the glow seem fainter, while extreme temperatures and high humidity can degrade the pigment’s light-emitting capabilities over time.

Substrate Color and Material: As mentioned earlier, using photoluminescent pigments on dark or absorbent surfaces can hinder their ability to glow brightly because these surfaces do not reflect light effectively.

To maximize the glow duration and brightness of photoluminescent pigments:

- Ensure they are charged with strong, direct light from an effective source like sunlight or UV light.

- Use high-quality pigments and apply them over light-colored or reflective surfaces.

- Minimize exposure to adverse environmental conditions by choosing the right settings and protective coatings if necessary.

By understanding and managing these factors, the brightness and longevity of photoluminescent pigments can be significantly enhanced.

Why Can Photoluminescent Pigments Cause Darkening in Some Plastics?

Photoluminescent pigments can sometimes darken in plastics due to interactions during the extrusion process. Here’s a more detailed explanation:

During the plastic extrusion process, the materials are heated and forced through metal equipment, which can lead to friction between the photoluminescent pigments and the metal parts. This friction, combined with the heat, may cause the pigments to darken or appear gray. To mitigate this issue, it is recommended to minimize the contact time between the pigments and metal surfaces during extrusion. Additionally, using equipment specifically modified to reduce friction and prevent pigment degradation can help maintain the color and brightness of the photoluminescent pigments in the final plastic product.

What Is the Shelf Life of Photoluminescent Pigments?

The shelf life of photoluminescent pigments generally depends on several factors, but under optimal storage conditions, they can last for several years, typically around 5 to 10 years.

To ensure maximum shelf life, consider the following storage recommendations:

Keep in a Cool, Dry Place: Exposure to heat and moisture can degrade the pigments over time, reducing their glow efficiency. Storing them in a cool, dry environment helps maintain their chemical stability.

Proper Sealing: Photoluminescent pigments should be stored in an airtight container to prevent exposure to moisture and other environmental contaminants.

Avoid Mechanical Stress: Keeping the pigments in a stable environment where they are not subjected to continuous movement or pressure helps prevent physical damage to the particles, which can affect their luminous efficiency.

By adhering to these storage conditions, you can help ensure that the photoluminescent pigments retain their effectiveness and are ready for use when needed.

Are Photoluminescent Pigments Harmful to Humans?

Yes. Photoluminescent pigments, particularly those made from strontium aluminate, are generally considered safe for humans. These pigments are non-toxic and do not emit radiation, making them suitable for a wide range of applications, including those that involve direct contact with the human body, such as textiles and toys. Here’s a closer look at their safety:

Non-toxic Composition: The primary materials used in these pigments, such as strontium aluminate, are inert and non-radioactive. They do not degrade into harmful substances under normal environmental and usage conditions.

No Radiation: Unlike some other luminescent materials that might contain radioactive elements, photoluminescent pigments do not contain any radioactive materials and do not emit any form of radiation.

Compliance with Safety Standards: Quality photoluminescent pigments are manufactured to meet international safety standards, including REACH and RoHS, which ensure that they are free from harmful substances like lead, cadmium, and other heavy metals.

Stability: These pigments are stable under normal conditions and do not react chemically in a way that would release harmful substances. Their chemical stability also contributes to their safety in various applications.

While photoluminescent pigments are safe for use in consumer products, it is always important to follow manufacturer guidelines regarding their proper handling and use, especially in sensitive applications. For industrial uses, standard safety practices such as using appropriate personal protective equipment (PPE) should be followed to handle bulk quantities.

What is the Recommended Mixing Ratio of Photoluminescent Pigment to Ink for Printing?

For optimal results, it is generally recommended to mix photoluminescent pigment with ink at a 1:1 ratio. To achieve the best luminosity, a printing thickness of at least 0.25 mm is advised. With this ratio and thickness, one kilogram of pigment can cover approximately 2 square meters if applied fully across the surface. However, as most products feature partial glow-in-the-dark designs, the actual coverage will depend on the proportion of the area that requires the photoluminescent effect.

Conclusion

Understanding and utilizing photoluminescent pigments effectively can transform the functionality and aesthetics of your products. Whether you are integrating these pigments into plastics, inks, or other materials, knowing the right application techniques, storage methods, and safety protocols is crucial. With Glowinking pigments, you can achieve a brilliant and lasting glow that is both safe and eco-friendly. For further assistance or to explore customized pigment solutions that cater specifically to your needs, feel free to contact us at Glowinking. We are committed to providing you with high-quality materials and expert guidance to make your projects shine.