Your Trusted Source for Advanced Pearlescent Pigments

Your Partner in Creating Stunning, Long-Lasting Finishes Across Multiple Industries

Enhance the beauty and market value of your products with our industry-leading pearlescent pigments. Perfect for creating captivating finishes that meet the demands of high-end automotive, cosmetic, and industrial markets.

Why Choose Our Pearlescent Pigments?

Our pearlescent pigments give you intense color, ultra-fine texture, and exceptional gloss. They’re engineered to give you superior coverage, chemical resistance, and ease of use, so you get a flawless finish on any surface.

Expert Assistance Awaits

Have more questions or unique requirements? Reach out to our experts today.

Explore Our Pearlescent Pigment Collections

Check out our wide range of pearlescent pigments that make your creations pop. We’ve got everything from bold colors to soft shimmers, so you can find the perfect fit for any project.

Transformative Color Solutions for Every Industry!

Glowinking’s Pearlescent Pigments give you unbeatable color and flexibility. They’re made to make your products look amazing, no matter what you’re using them for.

- High-quality, non-toxic formulations

- Excellent gloss and luster

- Wide range of colors and effects

- Ideal for automotive, cosmetics, and coatings

- Long-lasting durability and color stability

Hot Selling Series Of Our Pearlescent Pigments

Take a look at our best-selling pigments, picked by top manufacturers for their amazing color and how easy they are to use. Make your products the best they can be with the best pigments out there.

Top-Selling Pearlescent Pigments

Our Colored Series is all about bold expression. These vibrant pigments provide rich color depth, ideal for eye-catching designs.

Get a little bit of magic with our Fairy Series. These soft, shimmery pigments are perfect for cosmetics and art projects when you want a little something extra.

Stand out with our Chameleon Series. These innovative pigments shift colors, creating a dynamic look that captures attention from every angle.

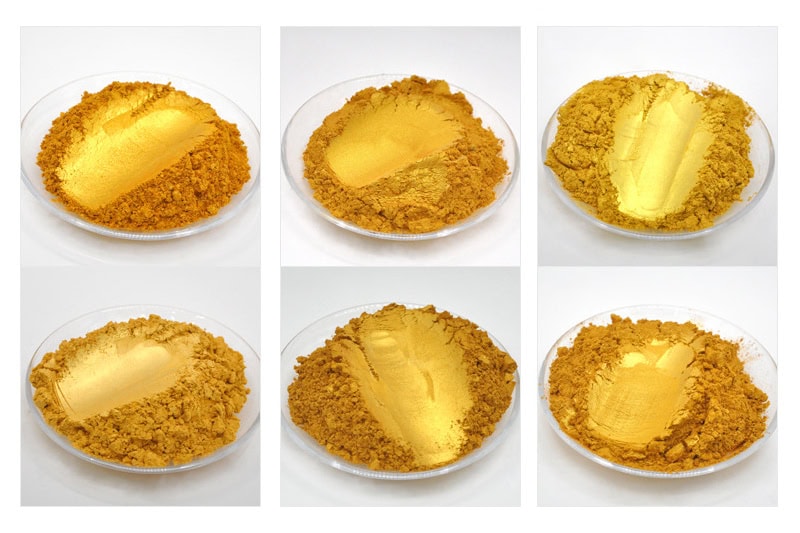

Infuse your products with luxury using our Gold Series. Rich, metallic pigments provide a striking, high-end finish that impresses.

Certified Quality

Applications and Mixing Guidelines For Pearlescent Pigments

Discover the best applications for pearlescent pigments and get the right mixing ratios to enhance the aesthetic quality of your creations.

Coatings

Use our pearlescent pigments to make different surfaces look more attractive. These pigments provide amazing color depth and shine for automotive and architectural coatings.

- Removable Automotive Coatings 2-5% by weight

- Standard Automotive Clear Coats 2-5% by weight

- Appliance Paint and Coatings 2-5% by weight

- Wallpaper and Other Paper Coatings for Buildings 1-5% by weight

- Building Coatings for Indoor and Outdoor Use 10-20% by weight

Printing Inks

Change your designs with our pearlescent pigments used in graphic inks and screen printing. They provide bright colors and striking effects that grab people’s attention.

- Offset Printing Ink 5-10% by weight

- Textile Inks And Pastes 5-10% by weight

- Gravure Inks 5-15% by weight

- Screen Printing Inks 10-30% by weight

- Flexographic Inks 15-25% by weight

Industrial & Plastics

Our pearlescent pigments are tough and give a rich, shiny look to industrial coatings, plastics, and glass, making sure they stay visually impressive for a long time.

- Plastic Resins 0.2-0.5% by weight

- Plastic Bottles 1-2% by weight

- Glass 1-10% by weight

- Candles 5-10% by weight

- Rubber Polymers And Latex 5-15% by weight

- Masterbatch 10-30% by weight

Cosmetics

Give your cosmetic products a glamorous look with our pearlescent pigments. They add a luxurious finish and make makeup and skincare products more attractive.

- Shampoo 0.1-2% by weight

- Soaps 1-5% by weight

- Lotions 1-5% by weight

- Lipstick And Pigmented Lipgloss 5-10% by weight

- Nail Polish 5-25% by weight

- Eyeshadow 15-80% by weight

Why Choose Glowinking?

Glowinking specializes in the design and manufacture of high-quality pearlescent pigments for various industries. We provide a diverse range of standard and customized solutions to meet the unique needs of automotive, cosmetic, and industrial applications.

Your Trusted Partner for Pearlescent Pigments

Glowinking Innovations stands out as a premier manufacturer of pearlescent pigments.

- Certified by ISO9001 and REACH, ensuring quality and compliance.

- Advanced production technology that guarantees consistency and performance.

- Direct manufacturing capabilities for large-scale production with a skilled workforce.

What People Are Saying

Quality and innovation are at the heart of Glowinking, but our customers’ voices truly tell our story. Explore their testimonials to see how our pearlescent pigments have helped them achieve stunning results and gain a competitive edge.

Luca Rossi

Italy

At our factory, quality is everything, and Glowinking has never let us down. Their pigments are top-notch and consistently deliver the results we need. Plus, their customer support team is always ready to help with any questions. I couldn’t ask for a better partner.

Aisha Khan

UAE

Glowinking’s pigments have truly elevated our packaging design game. We’ve seen a noticeable increase in shelf appeal, and our products stand out in a crowded market. It’s amazing how much of a difference high-quality pigments can make!

John Smith

USA

We’ve been using Glowinking’s pigments for several projects, and the results have been fantastic. The precision in color and vibrancy has taken our products to the next level. Plus, the team is incredibly responsive and helpful. It feels great to work with such a dedicated company!

Carlos Mendez

Mexico

Glowinking has become our go-to supplier for pearlescent pigments. The quality is consistently excellent, and the team is always there to help with any specific needs we have. I’m impressed with how reliable they are, and it makes my job so much easier.

Complete Buyer’s Guide to Pearlescent Pigments

In the world of coatings and inks, it’s important for manufacturers to understand the ins and outs of pearlescent pigments. These special pigments not only make things look pretty, but they also have a wide range of uses across different industries. Let’s take a look at the different types of pearlescent pigments, what they’re used for, and how safe they are.

Table of Contents

What Are Pearlescent Pigments?

Pearlescent pigment is a type of pigment that is used to create a shimmering or iridescent effect, similar to the natural luster of pearls. These pigments are composed of tiny, flat, reflective particles that can reflect and refract light, creating a multi-dimensional, shiny appearance. The effect is often achieved by using mica-based particles coated with metal oxides, such as titanium dioxide, which enhance their reflective properties.

What are the Different Types of Pearlescent Pigments?

Pearlescent pigments can be classified into several categories based on their composition and light-reflective properties. The most common types include:

Natural Pearl Essence:

Natural pearl essence is made from real fish scales, which gives it a unique, genuine pearl-like look. However, it is rarely used in modern manufacturing because of ethical and supply chain issues. When it is used, natural pearl essence is reserved for luxury applications, like high-end automotive finishes and designer cosmetics, because it is rare and expensive.

Bismuth Oxychloride:

This synthetic compound provides a bright, metallic shine that is commonly used in cosmetics. Bismuth oxychloride is popular because it can create smooth, pearlescent effects without feeling gritty. It is used in foundations, eyeshadows, and nail polishes. Besides cosmetics, it is used in decorative plastics and coatings because it is stable and has a long-lasting shine.

Titanium Dioxide (TiO2) Coated Mica:

Mica is a natural mineral that is often used as a base for pearlescent pigments. Titanium dioxide-coated mica creates bright white or silvery effects and is commonly used in automotive and decorative paints. It has high opacity and great coverage, which makes it perfect for high-end automotive coatings that need a pearlescent finish.

Iron Oxide Coated Mica:

Iron oxide-coated mica creates warm colors like gold, bronze, and copper. This type of pearlescent pigment is often used in printing inks, plastics, and coatings, especially when a more metallic or earthy color is wanted. The reflective properties of iron oxide-coated mica pigments also add depth to automotive paints and offer bright color choices for printing and packaging.

Colored Interference Pigments:

These pigments are made by layering mica with different metal oxides to create special color-shifting effects. Depending on the angle of light, the color seems to change, which gives them an iridescent look. This characteristic makes them very popular in luxury automotive finishes, high-end packaging, and premium cosmetics where you need a visually striking impact.

Is Mica-Based Pearlescent Pigment Safe to Eat?

Mica-based pearlescent pigments are generally considered safe for use in food. In the US, they are exempt from certification as color additives and can be used in different food products, like cereals, candies, and nutritional supplements, at levels up to 1.25% by weight. However, it’s important to make sure that any pigments used in food meet local safety regulations.

What is Pearlescent Pigment Powder Used For?

Pearlescent pigments are widely used in various industries because they are versatile and look good. Here are the main uses:

Automotive Coatings:

Pearlescent pigments are used in automotive coatings to create a deep, shiny effect on vehicle finishes. The shiny quality adds depth, making the surface look glossy and dynamic as light bounces off the pigments. This is especially popular in high-end cars, motorcycles, and custom paint jobs where the goal is to create a high-end, eye-catching look.

These pigments are often mixed with other metallic or color pigments to create a range of looks, from subtle gloss to dramatic, color-shifting finishes.

Printing Inks:

Pearlescent pigments are used in the printing industry to create reflective inks for labels, packaging, and promotional materials. Adding these pigments gives printed items a high-end look and feel, often used for cosmetics, perfumes, or luxury goods packaging. Their ability to catch and reflect light makes the product stand out on store shelves, adding a tactile element to marketing and branding.

Cosmetics:

In the beauty industry, pearlescent pigments are used to create shiny effects in makeup products like eyeshadows, highlighters, and nail polishes. They can add sparkle or a dewy finish, depending on the formula. Bismuth oxychloride, in particular, is widely used in high-end cosmetics because it goes on smooth and gives a radiant finish.

Decorative Coatings:

For arts, crafts, and home décor, pearlescent pigments are often added to paints and coatings to create a high-end, shiny look. These pigments are used on ceramics, sculptures, and decorative items to give them a shiny, opalescent finish. They also show up in interior design applications like wall paints and flooring treatments to create beautiful, reflective surfaces in living spaces.

Plastics and Moldings:

In the plastics industry, pearlescent pigments are used to add a metallic or pearlescent finish to molded products. These pigments are mixed into the plastic resins before molding, giving the final product a smooth, reflective surface. This is commonly seen in high-end consumer goods, electronic device casings, and packaging materials where how it looks is important.

How Do You Mix Pearl Pigments?

Mixing pearlescent pigments is a precise process to get consistent results. Depending on what you’re doing, you’ll need to adjust the pigment concentration and binder to get the effect you want. Here’s a general guide to mixing pearl pigments:

Automotive Paints:

For a full-body paint job, you’ll typically use about 15-20 grams of pearlescent pigment per liter of binder. For custom finishes, you can experiment with mixing different pearlescent pigments to get unique effects. It’s important to make sure the pigments are evenly dispersed in the binder so they don’t clump up and cause uneven finishes.

Printing Inks:

When you’re printing, the ratio of pigment to ink is important. If you use too much pigment, it can clog up your print heads or give you inconsistent prints. If you use too little, you won’t get the shimmering effect you want. As a starting point, you’ll usually use about 5-10% of pearlescent pigment by weight.

Cosmetics:

When you’re making makeup, especially powders, it’s important to mix pearlescent pigments evenly so they go on smooth. You’ll usually mix the pigments with fillers and binders at a concentration of about 1-5%, depending on how much shimmer you want.

Environmental Considerations in Pearlescent Pigment Manufacturing

As people become more aware of the environment, the production of pearlescent pigments is changing to be more sustainable. Traditional pigments, especially ones with metallic coatings, can have a big impact on the environment because of how they’re mined and processed. But the industry is working on more eco-friendly options, like:

Synthetic Mica:

Instead of mining natural mica, which can cause environmental problems, synthetic mica is made in labs under controlled conditions. It has the same reflective properties without the environmental impact.

Water-Based Coatings:

They’re working on water-based systems for dispersing pearlescent pigments to reduce the need for solvent-based systems, which release volatile organic compounds (VOCs) into the environment.

Recyclable and Biodegradable Packaging:

In the cosmetics and printing industries, there’s a growing demand for products that have pearlescent pigments but are packaged in materials that can be recycled or break down naturally, so they don’t have as much of an impact on the environment.

Choosing the Right Pearlescent Pigment for Your Application

When you’re picking pearlescent pigments, there are a few things to think about because they all affect how it looks in the end:

What You’re Using It For:

What you’re doing with it is going to be the biggest factor in what kind of pigment you need. Automotive coatings might need pigments that can handle high heat or are more durable, while cosmetics need pigments that are safe for skin contact and give a smooth texture.

What You Want It to Look Like:

If you want a subtle shimmer, you’ll want to use finer pigments that give a soft, satin-like finish. If you want something more dramatic and iridescent, you’ll want to use pigments with bigger particles or ones that change color depending on how you look at them.

What Works Together

You’ll want to make sure the pigments you’re using work with the binder or medium you’re using. Some pigments might react with certain chemicals, which can mess up how it looks or even be a safety concern, especially in cosmetics.

Future Trends in Pearlescent Pigments

The pearlescent pigment industry is changing because of new technology and what people want. Some of the big trends are:

Being More Sustainable:

Like I said before, people are looking for more eco-friendly options, like synthetic mica and water-based stuff. Companies are investing in greener technology to make pigments with less of an impact on the environment.

Nanotechnology:

Because of advances in nanotechnology, they can make pearlescent pigments with even smaller particles. That means they go on smoother and give a more refined finish, especially in cosmetics and automotive paints.

Color-Shifting Pigments:

Iridescent and color-shifting pigments are getting more popular, especially in luxury stuff. These pigments change color depending on how you look at them, so they give you a cool, eye-catching effect.

Conclusion

In conclusion, pearlescent pigments give manufacturers a lot of options to make their products look good and do what they’re supposed to do. By picking the right pigment, using the right mixing techniques, and keeping up with what’s going on in the industry, you can make really cool, high-quality finishes that make your stuff stand out.

For further assistance or to explore customized pigment solutions that cater specifically to your needs, feel free to contact us at Glowinking. We are committed to providing you with high-quality materials and expert guidance to make your projects shine.