Adding pearlescent pigment to your car paint can make it look amazing. To use it, mix a little bit of pearlescent pigment with a reducer and dust it onto the color coat for a satin finish. This is how manufacturers make cool colors that really stand out. Knowing how to mix and apply pearlescent pigment is important if you want your paint job to look good.

Understanding Pearlescent Pigment

Pearlescent pigment is made from natural or synthetic sources and is made up of tiny particles that reflect light in different ways. These particles can be different sizes, shapes, and colors, which all affect how the paint looks. The cool, shiny look of pearlescent pigment comes from the way the layers of the pigment reflect and bend light when you look at it from different angles.

Composition and Properties

- Natural vs. Synthetic: Natural pearlescent pigment is made from real pearls, while synthetic versions are made to look like pearls. Each type has its own benefits; natural powder usually has more depth, while synthetic options can come in more colors.

- Particle Size: The size of the pearlescent pigment particles affects the finish. Finer powders yield a more subtle shimmer, while coarser particles can create a more pronounced effect.

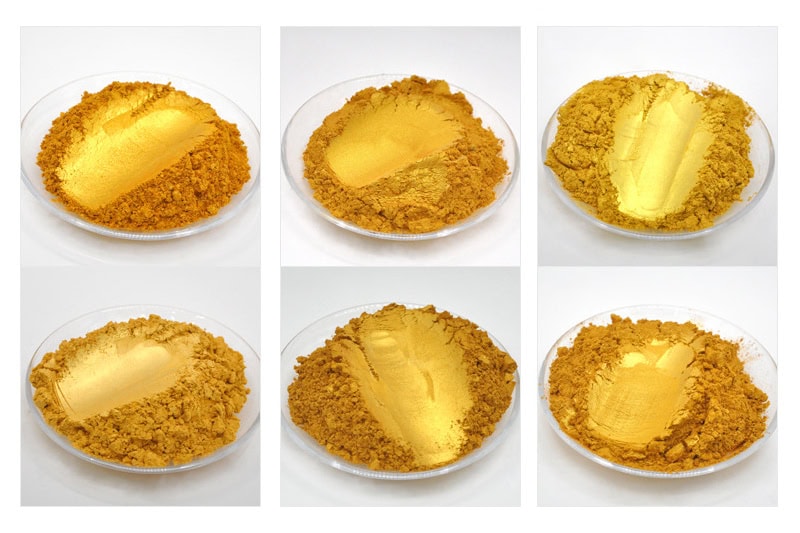

- Colors: You can get pearlescent pigment in all kinds of colors, so you can make your paint job look exactly how you want it to. If you mix different colored powders together, you can make your own custom colors. Here are the color ranges of pearlescent pigments from Glowinking:

Top-Selling Pearlescent Pigments

How Much Pearlescent Pigment to Add in Paint?

How much pearlescent pigment you need depends on what you want your paint job to look like. For a normal mix, you should use about 15 grams of pearl pigment for every liter of paint. That way, you’ll get a cool, shiny look without covering up the color of the paint.

Detailed Ratios and Effects

Light Effect: For a subtle shine, use 5-10 grams per liter. This allows for a hint of iridescence without overwhelming the color.

Medium Effect: For a balanced shimmer, stick to the standard 15 grams. This ratio provides a noticeable pearl effect while maintaining color integrity.

Heavy Effect: For a dramatic look, increase the amount to 20-30 grams. This approach works well for custom cars or special edition models that aim to stand out.

Step-by-Step Guide to Mixing Pearlescent Pigments

1. Prepare Your Materials:

- Gather clear paint (varnish or matte paint).

- Obtain the desired pearlescent pigment.

- Use a clean mixing container and tools.

2. Mixing Process:

- Pour the clear paint into the container.

- Gradually add the pearlescent pigment according to the desired ratio (around 10% of the clear paint volume).

- Stir thoroughly until no particles remain visible. Use a mechanical mixer if available for a more even blend.

- Let the mixture sit for a moment before use, allowing air bubbles to escape.

3. Application:

- Apply the mixture in thin, even coats using a spray gun or airbrush for best results.

- Allow each layer to dry completely before applying additional coats. This ensures a uniform finish.

Benefits of Using Pearlescent Pigment in Car Paint

Using pearlescent pigment in car paint provides numerous advantages:

Looks: The shiny effect makes the car look better, so it’s more attractive to people who might want to buy it.

Durability: Pearlescent paint is usually better at resisting weather than regular paint, so it helps protect the car from the sun and other stuff outside.

Make it your own: Pearlescent paint can be changed a lot, so car companies can make different colors and looks that people want to buy.

Resale Value: Cars with pearlescent finishes can fetch higher prices when you sell them because they look good.

Differences Between Pearlescent and Metallic Paint

While both pearlescent and metallic paints have shiny particles in them, they look different.

Pearlescent Paint: Uses shiny stuff to make the paint look like it changes color when you look at it from different angles. This makes the car look cooler.

Metallic Paint: Reflects light so the paint looks like it has layers. It has shiny flakes in it, which makes the car look sparkly.

Both types are durable and resistant to wear, making them excellent choices for car manufacturers looking to elevate their products.

Precautions When Using pearlescent pigment

Mix with Clear Pigments: Avoid mixing pearlescent pigment with opaque pigments like titanium white, as this can dull the shimmering effect. Clear pigments allow the iridescence to shine through.

Use Appropriate Ratios: Maintaining the correct ratio is critical; too much pearlescent pigment can disrupt the orientation of pigment sheets, leading to poor results.

Test Your Mixture: Always test a small batch before full application to ensure the desired effect. This can prevent costly mistakes during production.

How to Maintain Pearlescent Car Paint

To keep pearlescent paint looking fresh, follow these advanced maintenance techniques:

Regular Cleaning: Use non-abrasive cleaners to prevent scratching the paint surface. Avoid automatic car washes that use brushes; instead, hand wash with soft cloths.

Waxing: Regularly wax the vehicle to maintain shine and protect the paint. Use high-quality waxes designed specifically for pearlescent finishes.

Professional Maintenance: Consider periodic professional detailing for optimal care. Professionals can apply protective coatings that enhance the longevity of the paint.

Avoid Harsh Chemicals: Stay away from cleaners with harsh chemicals, as they can degrade the finish over time.

Store Properly: If possible, keep vehicles in garages or under covers to protect them from harsh weather conditions and UV exposure.

Common Mistakes to Avoid with pearlescent pigment

Overuse: Adding too much pearlescent pigment can overwhelm the base color, leading to a chaotic appearance. Stick to recommended ratios for the best results.

Inadequate Mixing: Failing to thoroughly mix the powder can lead to uneven application and patchiness. Ensure a consistent blend before application.

Neglecting Testing: Always test on a small area before proceeding with the entire vehicle. This allows for adjustments before the final application.

Ignoring Environmental Conditions: Applying paint in inappropriate weather (e.g., high humidity or extreme heat) can affect adhesion and finish. Choose ideal conditions for painting.

Forgetting about Drying Times: Not allowing adequate drying time between coats can lead to a compromised finish. Be patient and allow each layer to cure properly.

Summary

Regular maintenance and the right mixing techniques are key to preserving the luster of pearl-painted vehicles. By understanding the correct usage of pearlescent pigment, manufacturers can elevate their products’ visual appeal and durability. With careful attention to mixing, application, and maintenance, the benefits of pearlescent pigment will shine through, capturing the attention of consumers and enhancing the overall value of the vehicles.