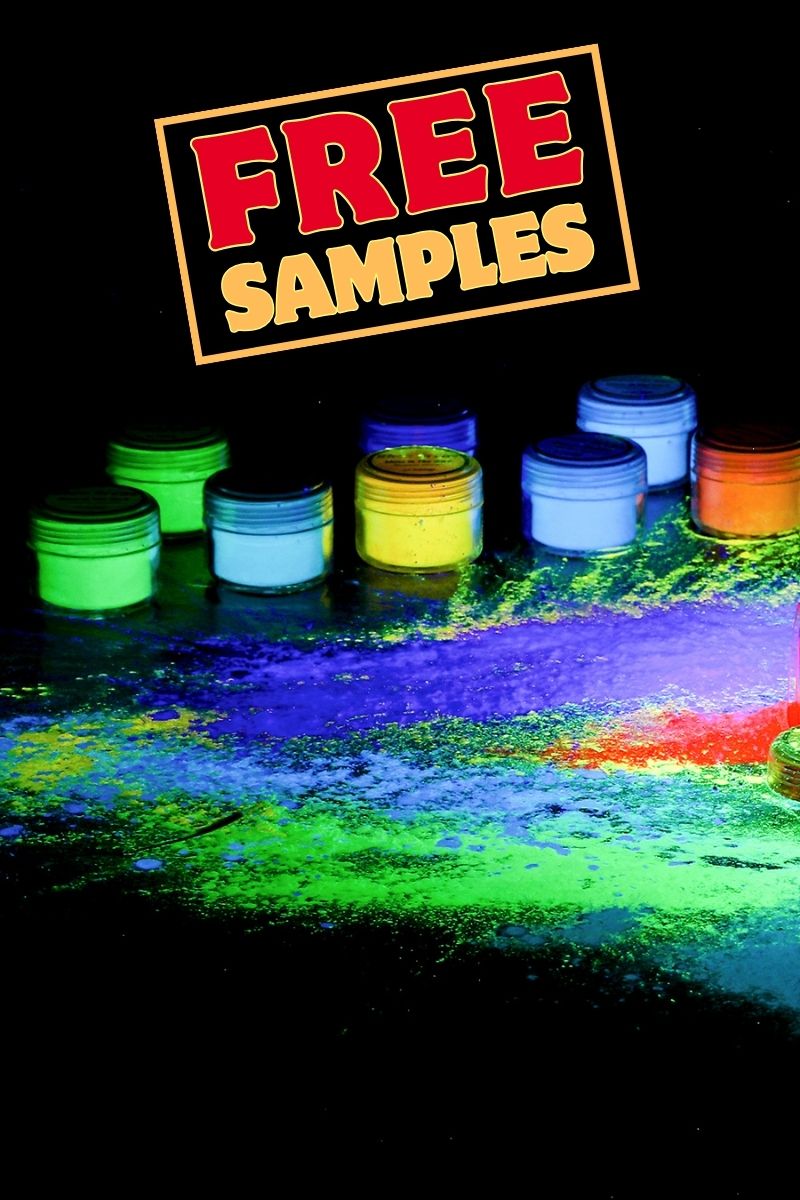

Reveal Hidden Brilliance with UV Reactive Powders

Invisible in daylight, vibrant under UV light

Experience the magic of pigments that stay discreet until exposed to UV light, bringing your projects to life with vibrant colors.

Explore Our Range of UV Reactive Powders

What are UV Reactive Powders

How they work

Also called invisible fluorescent powders, UV reactive powders are unique pigments that appear white or transparent under regular light but reveal bright, fluorescent colors when exposed to ultraviolet light.

UV reactive powders fluoresce under specific wavelengths of UV light—typically 254nm, 365nm, or 850nm—emitting bright colors. Their ability to remain invisible in daylight but glow under UV makes them ideal for security features, artistic projects, and specialty labels

Offers bright, striking fluorescence in a wide range of colors.

Vivid Colors

Highly soluble and disperses smoothly for effortless application.

Easy to Disperse

Withstand high temperatures without losing its fluorescent properties.

Heat Resistant

Manufactured using non-toxic materials, making it safe for various industries.

Non-Toxic

Certified Quality

Applications of UV Reactive Powders

UV reactive powders are widely used in anti-counterfeiting, security features, and creative design projects. Their ability to stay hidden under regular light and glow under UV makes them perfect for enhancing product security and visual appeal.

Security Printing

UV reactive powders are essential in security printing, adding invisible layers of protection to currency, IDs, and official documents, visible only under UV light.

Document Authentication

Used for banknotes, passports, and official documents, UV powders provide an invisible security layer visible only under specific UV light.

Product Labeling

Create unique, UV-visible labels and packaging with hidden elements that enhance brand recognition and stand out in UV-lit environments.

Creative Arts

Artists use UV powders to craft striking, glowing effects for performances, exhibitions, and custom artwork, revealing vivid colors under UV light.

Your Trusted Partner in UV Pigments

Glowinking is your go-to supplier for UV reactive pigments, combining industry expertise, a diverse product range, and a strong focus on eco-friendly solutions. Our commitment to quality and innovation sets us apart from the competition.

Why People Over The World Love Working With Us?

Global Reach, Local Support

We provide fast, reliable shipping and personalized support to customers worldwide, ensuring smooth operations and timely deliveries.

Unmatched Product Quality

Our UV reactive pigments are known for their superior brightness, durability, and performance, making us the top choice across industries.

Low MOQ and Fast Turnaround

We cater to businesses of all sizes with low minimum order quantities and quick production times, helping you scale efficiently.

What People Are Saying

At Glowinking, we’re all about quality, innovation, and customer satisfaction. But don’t just take our word for it. Hear what our customers have to say about their experiences with Glowinking.

Sophie Dupont

France

“Glowinking’s fluorescent pigments have brought a new level of creativity to our makeup products. The pigments are safe, high-quality, and deliver stunning results in our formulations.”

Sarah Mitchell

UK

“Glowinking’s fluorescent pigments are the best we’ve ever used. Their colors are incredibly vibrant and long-lasting, which has greatly enhanced our product line. Delivery was also impressively fast.”

Javier Martínez

Spain

“Working with Glowinking has been a great experience. Their pigments give our toys vibrant colors that kids love, and their customer service is always responsive and helpful.”

David Green

USA

“We’ve been sourcing fluorescent pigments from Glowinking for several years, and they’ve never let us down. Their products are high-quality, durable, and consistently perform beyond expectations.”

More Related Products

Enhance your products with our range of specialty pigments, each offering unique visual effects for various applications.

Complete Buyer’s Guide to UV Reactive Powder

Got questions about our UV reactive powders? We’ve got answers. Our FAQ covers everything from product safety and customization options to durability and application. Use this guide to make informed decisions and get the most out of our vibrant pigments for your projects.

Table of Contents

What Is UV Reactive Powder?

UV reactive powder, also kown as invisible fluorescent pigment, is a unique pigment that appears white or pale under natural light but reveals vibrant, fluorescent colors when exposed to ultraviolet (UV) light. This makes it an ideal choice for covert applications, particularly in anti-counterfeiting printing, where hidden security features need to be invisible under normal conditions but clearly visible under UV light.

Commonly used in industries such as printing, packaging, and product authentication, UV reactive powder offers a discreet yet effective way to enhance security without altering the appearance of the printed material.

How Does UV Reactive Powder Work?

UV reactive powder works by absorbing UV light and re-emitting it as visible light, creating a glowing effect under UV or black light. Under regular daylight, these powders remain nearly invisible, making them perfect for security applications where covert markings are required. The hidden colors only become apparent under ultraviolet light, allowing for quick verification of authenticity.

Key characteristics of UV reactive powder include:

- White or light appearance under daylight.

- Vivid fluorescent glow under UV light, with colors like green, blue, red, and yellow.

- Immediate response to UV exposure, making it perfect for security checks and authentication.

Why Use UV Reactive Powder in Anti-Counterfeit Printing?

UV reactive powder plays a critical role in anti-counterfeit printing due to its ability to remain unseen until illuminated by UV light. This allows manufacturers and businesses to create hidden security features, such as logos, barcodes, or serial numbers, that cannot be easily replicated by counterfeiters.

Advantages of using UV reactive powder for anti-counterfeit applications:

- Invisibility under daylight: The powder is completely undetectable under normal lighting, ensuring that the design of the document or product remains unchanged.

- High-security marks: Only visible under UV light, making it difficult for counterfeiters to detect or duplicate.

- Customizable fluorescence: Different colors can be used for layered security, adding complexity to the counterfeit process.

- Quick validation: UV lights make it easy to authenticate genuine products, tickets, or documents in seconds.

Factors to Consider When Buying UV Reactive Powder

If you’re in the market for UV reactive powder, here are the key factors to consider:

- Brightness and Color: Choose a powder that provides a strong fluorescent glow under UV light. Brightness varies by product, so it’s important to select one that offers clear visibility for quick identification.

- Color Variations: UV reactive powder is available in multiple colors, such as green, blue, red, and yellow. Depending on your security requirements, you may choose different colors for specific applications to create complex verification layers.

- Ink Compatibility: Ensure that the UV reactive powder you purchase is compatible with the inks and printing methods you plan to use, such as offset, screen printing, or digital printing. Different powders mix differently with various inks and coatings.

- Non-Toxicity and Safety: It’s important to choose powders that comply with safety regulations, especially for use in consumer products or packaging. Look for non-toxic, formaldehyde-free options that are safe for all industries.

Common Applications of UV Reactive Powder

UV reactive powder is widely used across various industries, offering reliable, invisible security for a range of products. Common applications include:

- Anti-Counterfeit Printing: Banks, governments, and manufacturers use UV reactive powder to create hidden security features on banknotes, passports, ID cards, and other official documents. When examined under UV light, these features reveal the document’s authenticity.

- Product Authentication: UV reactive powder can be used to print covert logos or markings on packaging. This is especially important in industries where counterfeit goods are prevalent, such as pharmaceuticals, luxury goods, and electronics.

- Ticketing and Event Security: Event organizers and companies use UV reactive powder to mark tickets and passes with hidden, UV-reactive symbols or codes, making it easy to verify authenticity and prevent duplication.

- Security Labels and Stickers: Many products have UV-reactive security labels to prevent tampering or counterfeiting. These labels are invisible in regular light but show clear, glowing marks under UV light, ensuring only genuine products are verified.

How to Use UV Reactive Powder in Printing

Using UV reactive powder in printing processes is straightforward. Here’s how to integrate it into your production:

Mixing with Ink: UV reactive powder is mixed with clear or light-colored inks to maintain its invisible quality under daylight. It can also be combined with varnishes or coatings for an extra layer of protection on the printed material.

Printing Process: UV reactive powders are compatible with a wide range of printing methods, including offset printing, screen printing, and digital printing. Choose the method that best suits your production line and material type.

Application: After mixing, apply the ink-powder mixture onto your material, following the same steps as with regular ink. Once applied and dried, the markings remain invisible until exposed to UV light.

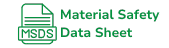

Testing: Always test the printed product under UV light to ensure the powder reacts properly and the fluorescent effect is as expected. This step is crucial for quality control, especially in high-security environments.

UV Reactive Powder vs. Traditional Fluorescent Powder

While both UV reactive powder and traditional fluorescent powder emit vibrant colors under UV light, they serve different purposes.

- UV Reactive Powder: Appears white or pale under daylight and is used for covert applications where the printed material needs to remain invisible until exposed to UV light.

- Traditional Fluorescent Powder: Has bright, visible colors even under normal light conditions. It’s often used for decorative purposes or in applications where visibility under regular lighting is important.

UV reactive powder is particularly suited for security applications, while traditional fluorescent powder is more commonly used for artistic, decorative, or high-visibility purposes.

UV Reactive Powder vs. Glow-in-the-Dark Powder: What’s the Difference?

A common question among potential buyers is how UV reactive powder differs from glow-in-the-dark powder. While both powders emit light, they function in different ways:

- UV Reactive Powder: This powder only glows under ultraviolet light. It is perfect for environments where black lights are present, such as clubs, theaters, or art installations.

- Glow-in-the-Dark Powder: This powder stores light energy from a light source (natural or artificial) and emits it in the dark without requiring a UV light source. It’s ideal for emergency lighting, safety signs, and outdoor decorations.

Both powders have their unique uses, and choosing between them depends on your specific needs and the intended environment.

How quickly can I receive my order?

We offer fast delivery with global shipping, ensuring your products arrive on time. Lead times may vary depending on the quantity and customization required, but we strive to deliver faster than the industry standard.

Conclusion

UV reactive powder is an essential tool for anti-counterfeit printing and security applications, offering invisible markings that only appear under UV light. By adding a hidden layer of protection to products, documents, and packaging, manufacturers can safeguard their products from counterfeiters and ensure authenticity.

When purchasing UV reactive powder, consider key factors such as brightness, ink compatibility, and color options to ensure the best results. Whether you’re using it for product authentication, event security, or document protection, this unique material provides an effective, covert solution for high-security needs.